Hello there!

This is my newest build, the TFE2.

I've used all Openbuilds extrusions, HGR20 rails and 1605 ballscrews on all axis'.

The bed is made up of 2 C-beams with 4040 stretchers. Then 8020 for the bed surface. The bed is attached from the top because I wanted the slats to be replaceable in case of oopsies and, once done, this machine will weigh a lot so I didn't fancy crawling underneath to replace slats or tighten bolts during maintenance, a lesson I learned from the original TFE.

The way they are secured can be seen here:

The underside of the bed is as follows:

And the top with a can of monster for scale:

The X-axis will be constructed in a similar way to the bed, with 2 C-beams and 4040 supports in between:

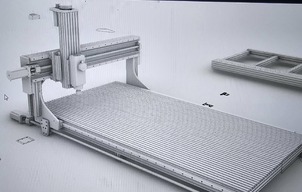

The machine when finished should hopefully resemble this: (But with extras like covers, drag chains ect.)

Important note about the Z-axis: I have gone with a belt coupled ballscrew since the Z-axis will be extremely heavy. I can easily achieve 1000mm/min with the original TFE using this setup, 20t on the stepper and 50t on the ballscrew. It's incredibly strong and 1000mm/min is more than enough for me.

The machining area will be roughly 1200x800mm with a Z of 140mm, which will allow me to later add a rotary axis.

The frame with rails attached:

And a picture of the original TFE:

This is the machine that will be cutting all the plates for the new build. Despite all 3D printed plates, it chews through aluminium like a dream.

This new build will also give me a chance to fully implement my compressor-free air blast!

TFE2 CNC Build

Build in 'Cartesian Style CNC' published by Mike_Mara, Aug 10, 2025 at 6:46 AM.

My TFE2 CNC Build. The TFE was much smaller and all of the gantry plates were 3D printed. Despite this it will happily machine aluminium without issue. So I decided to use that to make the TFE2 which will be all aluminium plates and much larger (1200x800mm machining area with roughly 140mm in Z so I can later add a rotary axis.)

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

Richard148 and Mark Carew like this. -

-

Build Author Mike_Mara, Find all builds by Mike_Mara

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - No Derivs - CC BY NC ND

Reason for this Build

I wanted a larger, more capable CNC router that would have good accuracy and rigidity to allow faster machining and tighter tolerances.

![[IMG]](https://builds.openbuilds.com/attachments/screenshot_20250810_105800_instagram-jpg.62879/)