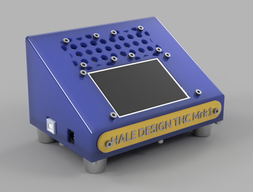

Standalone Torch Height Controller for CNC Plasma Cutting

Discussion in 'Laser Cutters' started by Retsaj, Oct 7, 2020.

Standalone Torch Height Controller for CNC Plasma Cutting

Discussion in 'Laser Cutters' started by Retsaj, Oct 7, 2020.

A Torch Height Controller helps improve plasma cut quality and can save a CNC Machine from crashing. This design doesn't require you to know electronics or need any custom circuits... Its plug and play! This is a COMPLETELY standalone controller with a built-in Driver powerful enough to run just about any stepper motor. (maybe a little to powerful for a NEMA17)

Page 2 of 3

Page 2 of 3