PrintAir CoreXY

Discussion in '3D printers' started by Keith Davis, Oct 3, 2015.

PrintAir CoreXY

Discussion in '3D printers' started by Keith Davis, Oct 3, 2015.

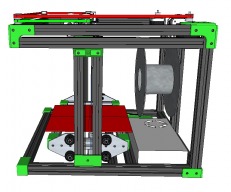

A CoreXY/Bowden design with a belt driven Z axis. This is a box design without the front end of the box, making the print area and maintenance, like changing a nozzle, easily accessible.

Page 1 of 2

Page 1 of 2