Original PhlatPrinter

Discussion in 'CNC Mills/Routers' started by Mark Carew, Nov 8, 2013.

Original PhlatPrinter

Discussion in 'CNC Mills/Routers' started by Mark Carew, Nov 8, 2013.

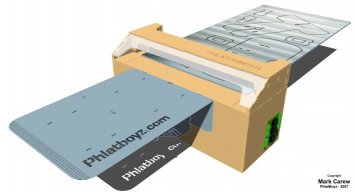

Phlatprinter foam cutting CNC machines are awesome space saving mills that use a rotary axis as a sheet feed.

Page 2 of 5

Page 2 of 5