Moag's CNC Mill

Discussion in 'CNC Mills/Routers' started by Moag, May 9, 2016.

Moag's CNC Mill

Discussion in 'CNC Mills/Routers' started by Moag, May 9, 2016.

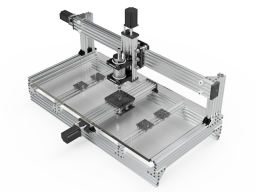

A design in progress, to 3D carve two-part Aluminium injection moulds for Soft Plastic Lures and Lead Jigs, so I can prototype some of the concepts rattling around in my head. All Openbuilds parts where possible, 1000x500mm footprint, 0.8kw Water-cooled Spindle?, High Torque Stepper?,Smoothieboard?, I still have no idea. As a newbie to the CNC world, any wisdom would be welcome to take this from just a idea into reality so I can start playing with all this awesome stuff. Thanks in advance

Page 3 of 4

Page 3 of 4