C-Beam to C-Beam XL Upgrade

Discussion in 'CNC Mills/Routers' started by SBLabs, Dec 6, 2016.

C-Beam to C-Beam XL Upgrade

Discussion in 'CNC Mills/Routers' started by SBLabs, Dec 6, 2016.

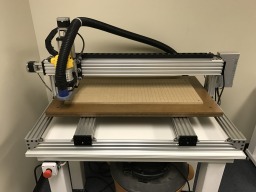

This is my first public build. Please be kind. We upgraded our C-Beam to the C-Cbeam X-Large. I want to give special thanks to Moag and the OpenBuilds team for making this happen.

Page 1 of 2

Page 1 of 2