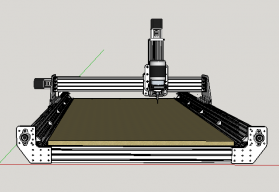

Lead Screw Driven Ox Derivative (850x1500)

Discussion in 'CNC Mills/Routers' started by Giarc, Mar 23, 2016.

ACME OX (A Lead Screw Driven Ox Derivative (850x1500))

Discussion in 'CNC Mills/Routers' started by Giarc, Mar 23, 2016.

Another build based on the original OX design with a cutting area will be about 26" (680mm) x 50" (1300mm) and driven by lead screws.

Page 2 of 4

Page 2 of 4