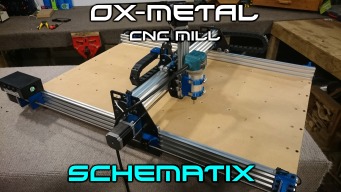

OX-Metal CNC Router Mill

Discussion in 'CNC Mills/Routers' started by Schematix, Jul 6, 2016.

OX-Metal CNC Router Mill

Discussion in 'CNC Mills/Routers' started by Schematix, Jul 6, 2016.

The OX-Metal is based on the original OX CNC mill But with a few modifications and add-ons

Page 4 of 4

Page 4 of 4