Sherline C-Beam with Offline Controller and MPG

Discussion in 'CNC Mills/Routers' started by James Evanko, Nov 22, 2018.

Sherline C-Beam with Offline Controller and MPG

Discussion in 'CNC Mills/Routers' started by James Evanko, Nov 22, 2018.

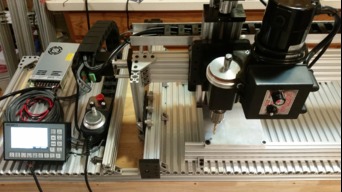

This is a C-Beam based router with V-rails used for the bed, a Sherline spindle with Jacobs chuck, closed loop stepper motors on every axis and an offline 4-axis CNC controller. A U-channel was created to guide the drag chain on the X-axis.