Rawcnc 1.5 Desktop Edition

Discussion in 'CNC Mills/Routers' started by roadss, Oct 22, 2017.

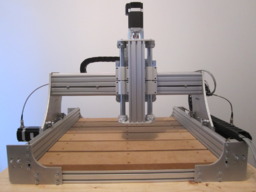

Rawcnc 1.5 Desktop Edition

Discussion in 'CNC Mills/Routers' started by roadss, Oct 22, 2017.

This will showcase the build of my Rawcnc 1.5. A rigid cnc router from the Swedish company Rawcnc, featuring a rather cool linear motion system, rack & pinion and steel reinforced X-axis capable of milling aluminum.

Page 1 of 2

Page 1 of 2