LS-LASER

Discussion in 'Laser Cutters' started by LukasK, Jun 26, 2018.

LS-LASER

Discussion in 'Laser Cutters' started by LukasK, Jun 26, 2018.

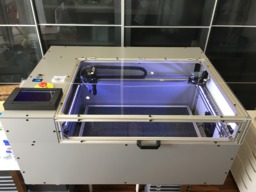

I have completed some custom build 3d printers (i3 and delta style) and a cnc mill based on v-slot and c-beam. From the beginning the cnc was built to fit/change between router, 5w led laser module and plotter pen. While all three works great, the build is primarily focused on heavy duty milling and brings some disadvantages when it comes to laser - slow because of leadscrew motion system and not as powerful because of “only” led laser. That is why I have started this build of co2 laser machine.

Page 2 of 2

Page 2 of 2