Sphinx Derived Router

Discussion in 'CNC Mills/Routers' started by Corey Corbin, Mar 8, 2020.

Sphinx Derived Router

Discussion in 'CNC Mills/Routers' started by Corey Corbin, Mar 8, 2020.

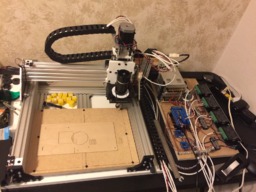

I Like the Sphinx design thought I would attempt my first build. I wanted to build this and use Arduino controller with GRBL to be able to learn and understand my machine.