Strong OX

Discussion in 'CNC Mills/Routers' started by Hytech2k, Nov 28, 2014.

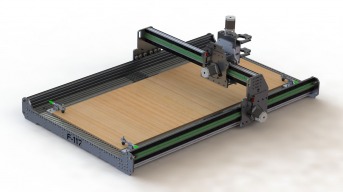

Area 51 CNC Parts F-117 CNC Gear Rack Drive System

Discussion in 'CNC Mills/Routers' started by Hytech2k, Nov 28, 2014.

This is my journey on building a rack and pinion Ox variant called the F-117 CNC.

Page 1 of 12

Page 1 of 12