Much4 - A printed version of the Laser V

Discussion in 'Laser Cutters' started by skarab, Jul 1, 2014.

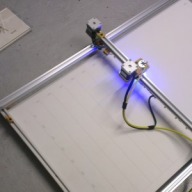

Much4 - LaserV printed version

Discussion in 'Laser Cutters' started by skarab, Jul 1, 2014.

By following the way of Robert Hummel, I drew a version of its exellent Laser V to use NEMA17 and easily printable parts.

Page 2 of 3

Page 2 of 3