Proteus

Discussion in '3D printers' started by Jovian, Nov 14, 2013.

Proteus

Discussion in '3D printers' started by Jovian, Nov 14, 2013.

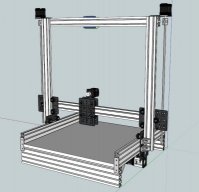

Proteus is the Greek God of change. Besides the numerous aspect of 3D printing that this could relate to this machine like the god can change. The Build allows for an interchanging head that will allow different functionality to be quickly and easily adapted. So you could print clay, silicon, plastic, cut with a laser cutter or even attach a rotary tool