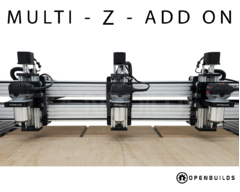

Multi Z LEAD Machine Addon

Discussion in 'CNC Mills/Routers' started by OpenBuilds, Dec 28, 2022.

Multi Z LEAD Machine Addon

Discussion in 'CNC Mills/Routers' started by OpenBuilds, Dec 28, 2022.

The Multi Z adds multiple Z axis to a LEAD CNC Machine allowing it to cut and carve 2 to 3 times the amount of projects in the tame it takes to make just one