openBuilds FreeBURN-2-Mini V-slot CO2 Laser (40-50w)

Discussion in 'Laser Cutters' started by openhardwarecoza, Jan 20, 2015.

openBuilds FreeBURN-2-Mini V-slot CO2 Laser (40-50w)

Discussion in 'Laser Cutters' started by openhardwarecoza, Jan 20, 2015.

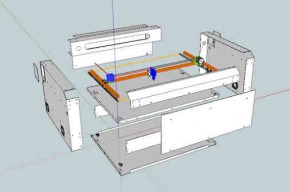

A new mini version of the http://openbuilds.com/builds/openbuilds-freeburn-1-v-slot-co2-laser-60-100w.1001/ FreeBurn CO2 Lasercutter

Page 4 of 5

Page 4 of 5