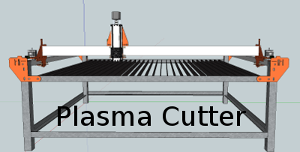

Plasma cutter - 608 on steel tube version

Discussion in 'Other Builds' started by openhardwarecoza, Apr 17, 2015.

Plasma cutter - 608 on steel tube version

Discussion in 'Other Builds' started by openhardwarecoza, Apr 17, 2015.

CNC Plasma cutter: 608ZZ on steel square tube linear rollers Welded frame HDT2-15 Belt Drive Tradeweld Cut-40 Plasma cutter with converted hand torch Virtual Torch Height Control through inductive probing - open source electronics project

Page 1 of 2

Page 1 of 2