CNC Hot Wire Cutter 4 Axis for Cutting Foam Wings

Discussion in 'Other Builds' started by Rusticalmond, Aug 27, 2015.

CNC Hot Wire Cutter 4 Axis for Cutting Foam Wings

Discussion in 'Other Builds' started by Rusticalmond, Aug 27, 2015.

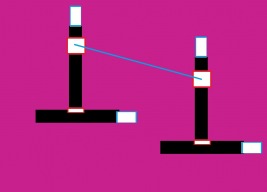

My build is to allow me to cut foam wings using CNC Hot Wire Cutter.

Page 1 of 3

Page 1 of 3