RONIN OX | The G10/Carbon Fiber Hogger

Discussion in 'CNC Mills/Routers' started by alex_b, Nov 19, 2015.

RONIN OX | The G10/Carbon Fiber Hogger

Discussion in 'CNC Mills/Routers' started by alex_b, Nov 19, 2015.

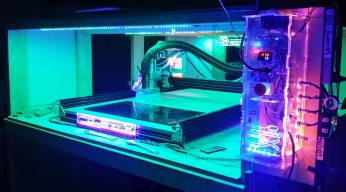

The Ronin OX is a dedicated fiber composite milling machine. I give a complete in-depth article on how to take a nearly stock OX build and easily turn it into something that can mill carbon fiber and G10 plate effectively and quickly.