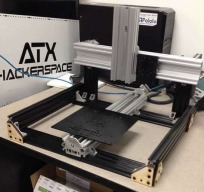

C-Beam Plate Machine

Discussion in 'CNC Mills/Routers' started by rc3105, Feb 23, 2016.

C-Beam Plate Machine

Discussion in 'CNC Mills/Routers' started by rc3105, Feb 23, 2016.

My first openbuilds submission, plain old c-beam machine. Seems like I've spent more time fighting the forum here redirecting in circles than actually building the machine. I'll try to add more pics if I ever find a path out of this corn maze...