V-slot CO2 Laser (60-100w)

Discussion in 'Laser Cutters' started by openhardwarecoza, Aug 9, 2014.

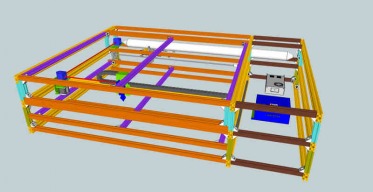

openBuilds FreeBURN-1 V-slot CO2 Laser (60-100w)

Discussion in 'Laser Cutters' started by openhardwarecoza, Aug 9, 2014.

DIY Lasercutter: Budget orientated, medium sized (60-100w), safety first, based on Lasersaur software toolchain

Page 2 of 3

Page 2 of 3