New Custom CNC

Discussion in 'CNC Mills/Routers' started by Goran crno, Apr 20, 2016.

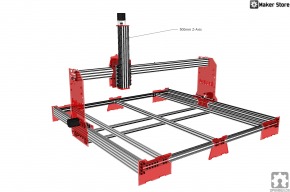

New Custom CNC with C-Beam Rails

Discussion in 'CNC Mills/Routers' started by Goran crno, Apr 20, 2016.

Hello all, wanted to share my custom build that I planed to do. My idea was to drill foam blocks to make molds for my projects. The CNC will be 1500-1500mm with a higher Z-Axis. So I redesigned the Gantry Plates that will be cut out at some other place. I hope you can share your opinion on my project.