3D Printer - Big Size

Discussion in '3D printers' started by AK-Creation, Dec 4, 2013.

3D Printer - Big Size

Discussion in '3D printers' started by AK-Creation, Dec 4, 2013.

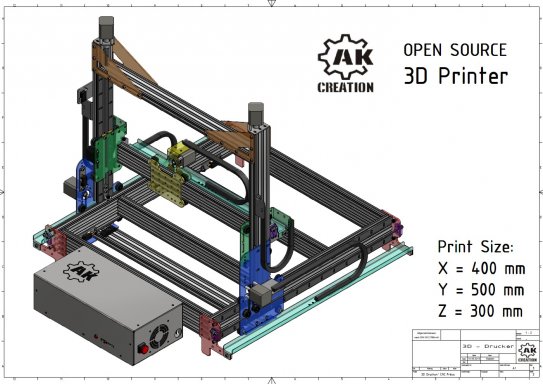

I creat a open source 3D Printer to print big things. Print size: 400x500x300 mm. You can download the Drawing in PDF and in Inventor 2013 format. The unwinding drawings are also included. I take some detail photos for a better understanding.

Page 1 of 2

Page 1 of 2