C-Beam based modular Resin Printer

Discussion in '3D printers' started by Jim S, Jul 20, 2016.

C-Beam based modular Resin Printer

Discussion in '3D printers' started by Jim S, Jul 20, 2016.

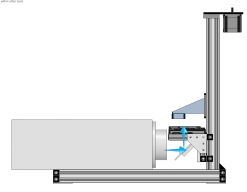

The build is based on a 500mm C-Beam and the SeeMeCNC FlexVat. The C-Beam is both the linear motion and a structural element of the design. The frame that holds the 45 degree first surface mirror and the build vat can slide up and down the C-Beam to accommodate projectors with lenses at different elevations.

Page 2 of 3

Page 2 of 3