CNC xPRO Driver

Discussion in 'Other Builds' started by Spark Concepts, May 25, 2014.

CNC xPRO Driver

Discussion in 'Other Builds' started by Spark Concepts, May 25, 2014.

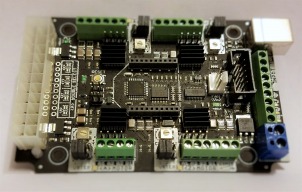

Spark Concepts CNC xPRO Driver. A new GRBL compatible, all-in-one stepper driver board with 4 motor controllers for XYZ + 1 clone (or rotary!). Capable of powering your next build with an ATX PSU (or 12V 2 wire supply), and ready for wireless printing. Compatible with Arduino (wireless robots anyone?)

Page 20 of 29

Page 20 of 29