Batxillerat Research Project: Design and construction of a CNC

Discussion in 'CNC Mills/Routers' started by Pol Feliu, Jul 6, 2014.

Batxillerat Research Project: Design and construction of a CNC

Discussion in 'CNC Mills/Routers' started by Pol Feliu, Jul 6, 2014.

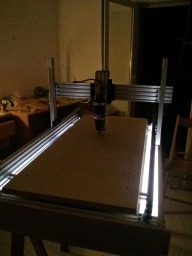

I'm working on a cartesian cnc router for my school research project