Maximus 3D Printer

Discussion in '3D printers' started by mytechno3d, Jul 16, 2014.

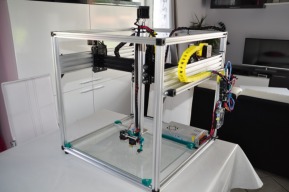

Maximus 3D Printer

Discussion in '3D printers' started by mytechno3d, Jul 16, 2014.

A full scalable 3D Printer , with a big printing area. Build with openbuild parts from www.vslot-europe.com

Page 1 of 3

Page 1 of 3