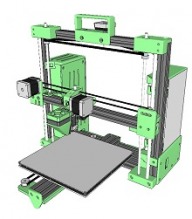

OneZ i3

Discussion in '3D printers' started by Keith Davis, Apr 17, 2016.

OneZ i3

Discussion in '3D printers' started by Keith Davis, Apr 17, 2016.

A quiet, 8inx8in build area, Cartesian printer with permanently level bed. This is a compact, solid, inexpensive printer that will reliably print any type filament for thousands of hours while you sleep, fish, or play ball in the park.

Page 7 of 7

Page 7 of 7