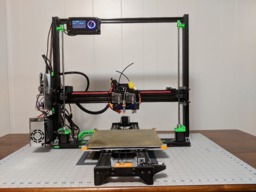

BinaryConstruct V3

Discussion in '3D printers' started by BinaryConstruct, Feb 28, 2018.

BinaryConstruct V3

Discussion in '3D printers' started by BinaryConstruct, Feb 28, 2018.

This printer is a design that has evolved over three years. The original goals of this project were to design a rigid printer that had a large print volume, 300mm^3, with easily sources parts and a minimum of complicated printed parts.