Dragon too Plasma cutter Mods (MetalGuru idea)

Discussion in 'Laser Cutters' started by mytechno3d, Apr 26, 2017.

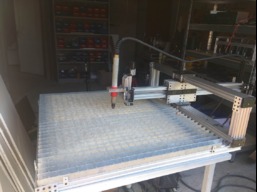

Dragon Plasma cutter

Discussion in 'Laser Cutters' started by mytechno3d, Apr 26, 2017.

Inspired by MetalGuru's idea : The plasma too cutter . If you have to cut small to medium sheet of steel with a plasma , this build may be for you

Page 1 of 2

Page 1 of 2