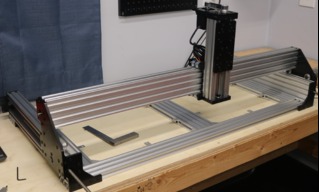

Sphinx 1050

Discussion in 'CNC Mills/Routers' started by Kyo, Nov 8, 2018.

Sphinx 1050

Discussion in 'CNC Mills/Routers' started by Kyo, Nov 8, 2018.

This is going to be a Sphinx 1050 build. Starting off as a stock kit build using industrial electronics and opensource control software. Mods and upgrades to follow.