Heavy Inexpensive CNC

Discussion in 'CNC Mills/Routers' started by Richard Bugland, Sep 28, 2014.

Heavy Inexpensive CNC

Discussion in 'CNC Mills/Routers' started by Richard Bugland, Sep 28, 2014.

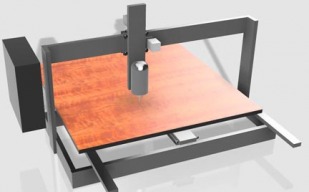

Acquiring a CNC has been on my list for some time now. This concept is a bare bones, upgradeable machine that will not require a complete rebuild when new parts become available. With a cutting surface over 36" square, this beast should be capable of creating its own parts. Lowering the price to make upgrading and making this contraption beefier, faster, and more precise.