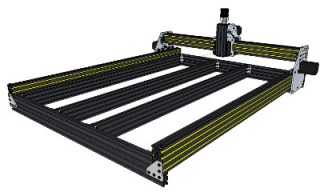

Black Angus : A Slightly "Beefier" OX

Discussion in 'CNC Mills/Routers' started by Nugz, Nov 6, 2014.

Angus : A Slightly "Beefier" OX

Discussion in 'CNC Mills/Routers' started by Nugz, Nov 6, 2014.

This is where I will share my attempt at building a slightly "beefier" OpenBuilds OX CNC Machine using commonly available parts in the spirit of OPENBUILDS and Open Source in general. I have a tendancy to over-build things so I will be balancing that tendacy against budget constraints and common sense as much as possible.