7050 Sphinx

Discussion in 'CNC Mills/Routers' started by Michael.M, Jul 15, 2017.

7050 Sphinx

Discussion in 'CNC Mills/Routers' started by Michael.M, Jul 15, 2017.

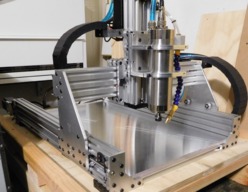

This is a Kyo Sphinx CNC Router build. Working Area: 350mm X 500mm Link to original design: https://openbuilds.com/builds/c-beam-sphinx.3605/

Page 4 of 13

Page 4 of 13