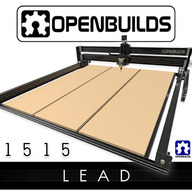

OpenBuilds LEAD CNC Machine 1515 (60" x 60")

Discussion in 'CNC Mills/Routers' started by OpenBuilds, Sep 29, 2020.

OpenBuilds LEAD CNC Machine 1515 (60" x 60")

Discussion in 'CNC Mills/Routers' started by OpenBuilds, Sep 29, 2020.

It began with creating an extremely rigid axis that incorporates a multi C-Beam Linear Rail system as well as precision lead screws coupled with a tension system for the absolute maximum in performance.

Page 6 of 7

Page 6 of 7