Hello openbuilders, my name is Pol Feliu. I live in Barcelona, Catalonia and I'm working on my "Treball de recerca" which is compulsory to get the Batxillerat title. I've always been curious about CNC's in general, so this is the subject I chose to elaborate during a year. For me its a good oportunity to have a big project to work with, and because it's a school project I have support from the teachers and some funding from my parents.

(Sorry if there's english mistakes, I'm working on it, any correction will be appreciate)

I've been looking for information about CNC's in general and it's hard to summarize what is a CNC. Therefore, until now, my work has been focused in coming up with a satisfying definition of it that most people will understand. The history of them it's also a bit blurry but I can't just make that up.

The worksheet isn't in English, because I must hand it in Catalan. Maybe if I finish the project, I'll translate it, but would be quite a lot of work for me. Anyway, here it is.

That's the first part of the work. I also decided that wanted to build an actual CNC machine. I don't have a workshop and my tools are limited, therefore i needed something which was easier to work with. Then I found openbuilds and the partstore, with the V-Slot system which I found really well-designed. I worked for many weeks to make a design of the machine and ordered the components to the part store.

One of the ideas that I had in mind is that I'd want to do as many things as I could from home, in order to reduce the costs and of course, for the fun of DYI.

The design of the motor control board is mine, but the drivers are from pololu. One of the most difficult things would be to develop the software that will power the brain of the machine. So I'm using a traditional way, an arduino with GRBL on it instead of developing the whole thing.

Some models and conceptart

Testing the Pololu drv8834 with a Nema17 motor

And with some more...

Then I put the circuit in a pcb format and made a homemade etching

Soldering the components and testing the board. Actually the first one came out wrong and I had to repeat it :S

Finally the board worked, it has some nice features (5 slots, individual fuses for each, microstepping configuration, 220µF caps for power stabilization).

Started to test some other components as the relay board for turning on and off the dremel (or the desired tool)

On Summer, Barcelona gets too warm, so we went to our village. There I had a room dedicated so I had lots of room. We were building on that room model railway but I put it in the wall aside

After some testing on breadboards I made the "distribution board" which includes a socket for the arduino 2560, the relay controller attached to the correct pins for grbl (cooling, spindle...), two fan controllers, pins for limit switches, pins for push buttons to pause, stop, and resume grbl execution... and of course the stepper control

Finally, after months waiting for (thanks to spain customs -.-) my openbuilds package arrived. I cut the V-slot to the required lenght in aluminium shop in Barcelona and went back to my village. There I checked if they were all, and the gantry plates I ordered were missing :O. I texted mark and the next day he sent me at the speed of the light my gantry plates.

While the package was on the go I started to build the base of the machine which I ended choosing wood. It's become very strong, and it has the right weight, not too much to carry and not too low to start moving when the machine is on. My local carpenter did a really good job. I gave him the V-slot extrusions prethreaded that had to go integrated with the wood and he adjusted the sizes to get a perfect fit

With the wooden base I started to mount all the electronic components in a board which is detachable from the structure so it's easy to repair if needed or just show the internal functioning. It's becoming a good tool to teach CNC works to starters in the field. I had a little problem with the height of the silentblocks (to damp any possible vibrations).

With the components secured in the board my carpenter did some lower surfaces on the front panel with a router to set all the controls/cables/LED indicators... Although I smoothed it with sandpaper the surface was rought and dirty so I painted just the holes and now its clean and looks good. Then I wired all the switches, buttons.... to the boards and installed a exhaust fan.

The front panel has the power input so I needed to wire it to the power supply. I also included a emergency button which kills the power, so it's not a good idea to press it in the middle of a job. I wired the ground protection to the power supply so in case of a wire touching the shield won't happen anything. The tool power which is switched on and off by the relay board doesnt' have ground protection because the dremel which I'm using doesn't have it neither. After I checked that all the wiring worked I installed a led strips which gives me a nice glare effect in the side corridors.

Finally the grantry plates arrived and started the "bridge" construction. One of the V-slot extrusions is damaged, I don't know if it came like that or I hit it with something.

When I was working on the Z-axis i found out that I ordered the wrong bearings and my 8mm rod didn't fit on those. I looked forward buying them online but the best choice was about one week of shipping. At the end i found a specialized shop near Barcelona which they had them. They cost me an arm and a leg but finally i could cut the threaded rod to lenght and install the axis with the dremel holder.

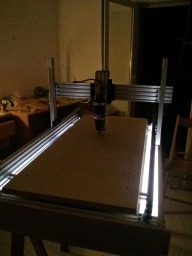

Finally the structure was finished.

I made a few extensor wires for the NEMA17 which I'm not really happy about them, the motors lose strengh and the voltage drops about half a volt (I think i'll replace them with a thicker wire someday). Nevertheless i configured grbl to the specifications and done a few tests with G-codes. Check out the nice circle which I did: http://goo.gl/CtufBB

Here's the link to g+photos:

https://plus.google.com/photos/115401297713036421724/albums/6029144926467815569

Batxillerat Research Project: Design and construction of a CNC

Build in 'Cartesian Style CNC' published by Pol Feliu, Sep 13, 2014.

I'm working on a cartesian cnc router for my school research project

-

-

-

- Build Progress:

-

- Build in Progress...

Attached Files:

-

-

Build Author Pol Feliu, Find all builds by Pol Feliu

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution Share Alike - CC BY SA

-

Parts list

Qty Part Name Part Link Comments 4 1/8" spacer Link 1 5mm * 8mm Flexible Coupling Link 3 5mm MXL Aluminum Timing Pulley Link 1 8mm Acme Nut Block Link 1 8mm Metric Lead Screw Link 3 Aluminum Spacers 1 - 1/2" Link 8 Aluminum Spacers 1-1/2" Link 2 Aluminum Spacers 1/4" Link 2 Ball Bearing 625 2RS Link 10 Dual V Wheel Kit - Delrin Link 12 Eccentric Spacers Link 4 Inside Hidden Corner Bracket Link 2 Lock Collar (8mm) Link 15 Low Profile Screws M5 15mm Link 4 Low Profile Screws M5 35mm Link 7 Low Profile Screws M5 40mm Link 65 Low Profile Screws M5 8mm Link 8 M3 Cap Head Screws 30mm Link 3 M3 Cap Head Screws 45mm Link 3 Motor Mount Plate Link 34 Nylon Insert Hex Locknut 5mm Link 6 OpenBuilds Solid V Wheel Kit Link 13 Slot Washer - 12x5x1.5mm Link 4 Socket Head Screws M3 8mm Link 2 Spacer Block (V-Slot) Link 44 Tee Nut Link 2 Threaded Rod Plate Link 4 Universal L Brackets Double Link 5 Universal L Brackets Triple Link 5 V-Slot Gantry Plate Link 11 MXL (1/4″) Timing Belt Link 2 V-Slot 20x20 500mm Link 2 V-Slot 20x20 300mm Link 2 V-Slot 20x40 580mm Link 1 V-Slot 20x60 293mm Link 2 V-Slot 20x80 1000mm Link 1 V-Slot 20x80 633,7mm Link 5 Pololu DRV8834 Link Low-Voltage Stepper Motor Driver 1 Arduino Mega 2560 R3 Link 1 5V 2-Canal Modulo rele Shield Link -

Attached Files:

-