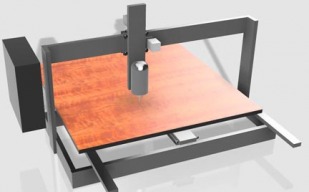

Inexpensive and heavy are not often used in the same sentence. My goal with this design is to create a CNC router that has a 36" cutting surface and remain at a low cost. Any and all criticism both for upgrades and design flaws will be gladly appreciated. My use for this will be cutting materials softer then aluminum. Bringing my design concepts to life. The idea here is creating an inexpensive machine without sacrificing quality. So inexpensive not cheap. Using belt and pinion drive systems and the shortest runs of the Gt3 timing belt keeps the price down allowing the use of Nema 23 motors. The Nema 17 are less expensive yes, but the performance of the 23's is better.

The X axis is the lower part of this machine. 36" inch cutting surface. Movement is created by a single actuator under the center of the spoiler board. Again with the minimal concept minimizing cost and also keep cutting chips out of the moving parts. Since the main actuator is in the center, it requires thin out runners to support the edges of the spoiler board. Im thinking about using felt so the cutting surface can slide on the out runners, then upgrading to wheels or bearings later. Final upgrade will be a second actuator, motor, and more wheels.

Y axis is a simple bridge style belt and pinion single motor actuator on a 1000mm or 1500mm 80x20 v slide. Supported by two pillars of single 80x20 bracing the horizontal bridge perpendicularly. The ganrty is two plates. One plate on either side of the Y axis bridge.

Z axis is directly connected to the Y axis gantry plate. This axis is made from the same 80x20 that makes up the previous components of the contraption. Also belt driven, this axis motor runs close to the router/cutting tool. This may be a redesigned later.

So far all the components for this build cost less then $600 USD. This does not include the $50 controller or computer that i have already.

Heavy Inexpensive CNC

Build in 'Other Style CNC Mills' published by Richard Bugland, Sep 28, 2014.

Acquiring a CNC has been on my list for some time now. This concept is a bare bones, upgradeable machine that will not require a complete rebuild when new parts become available. With a cutting surface over 36" square, this beast should be capable of creating its own parts. Lowering the price to make upgrading and making this contraption beefier, faster, and more precise.

-

-

-

- Build Progress:

-

- Build in Progress...

-

Special Notes

This design was reverse engineered. Stripping it down to the bare essentials to lower the cost without sacrificing quality. Once built it will be able to make its own parts for upgrades, bracing, precision, and speed. After the build is complete I will upload a parts list and real pics.

Lapi likes this. -

-

Build Author Richard Bugland, Find all builds by Richard Bugland

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution No Derivs - CC BY ND

Reason for this Build

To bring my design concepts to life. -

Attached Files:

-