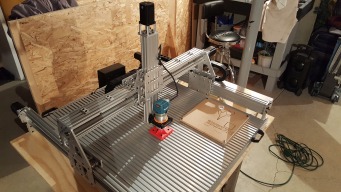

Update 12/02/16 - Completed my build. I have attached images of the build.. So far so good. I would like the "Z" axis to be a little stronger but it hasn't been a problem so far. I have some ideas on what I want to do in the future to add more strength. I used thrust bearings and ran my drive screws to pull instead of push. This helps tremendously with the noise and the whipping. I am also using the HT stepper motors with the V2 controller from OB. I don't get the full torque of the motors with this board but I haven't needed the extra torque yet. The "Y" axis is a little noisy but bot much. Overall it runs pretty quiet. I am using the Makita router because it has lower rpm's and that helped tons when I was cutting aluminum. - You can see pictures in the "Files and Drawings" tab above.

Update 06/25/16 - Added my final plate, test fit my home made "T" slot table using 20x80 v-rails, Still need to attach the motors and run some test but I wanted to get a feel of strength of the "Z". So far the overall unit is very strong compared to the c-beam machine I build awhile back. I have tried to push the router plate back and forth the "Y" and twist it about the "Z" so far it seams pretty strong. I can see a very tiny little bit of flex but I am convinced it is the extruded c-beam. The extrusions are not as strong as you think. Regardless, this is still a hobby CNC and it will never be as strong one build from machined parts. I have added some addition pictures in the document section of this build page.

Update 06/19/16 made most of my plates using the C-BEAM machine I built a few months ago. it took awhile because the z axis on the C-BEAM machine is not very strong and the 2 flute bit would grab and start walking. unfortunately this little machine is hit and miss on cutting aluminum. if you are a noobie this will frustrate you. needless to say my build is close. one more plate to add to the z axis to double up the plate and add more v rollers. I will update later adding motrs and controller.

Update*** Created my first set of plates. Every went fine until I could not get all of my rollers tight. I measured everything and checked CAD and parts from the Openbuilds Parts Store and all the dimensions matched. So I did what other had done, drilled out the screw holes and used Eccentric nuts. It was a little harder to get all aligned but it worked out....

This is the very early stage of my design. I have completed my build of the C-BEAM CNC machine with some minor upgrades. Now it is time to build a larger more robust machine combining the strong unique features of the C-BEAM along with the larger format and movable gantry of the OX CNC machine. This is still in development and may change slightly. I may be going overboard on the design as it relates to strength especially as the size will be limited to the 1000mm lead screws. I have been toying with the idea of using the steel "V" wheels along with the OpenRail™ Linear Rail instead of the Xtreme Solid V Wheel. I would like some input from others on what would be better/pro and cons. Any comments would be appreciated.

OX Super "C" - Cpmpleted 11/02/16

Build in 'Cartesian Style CNC' published by anigeek65, Dec 2, 2016.

This CNC utilizes the C-BEAM extruded aluminum for the "X", "Y", and "Z" axis. The gantry will move similar to the OX along with the "Z" except I am incorporating the C-BEAM instead of the 20x60 V-RAIL. To make the system as strong as possible I am using two C-BEAM rails back to back. The "Y" axis will encompass two sets of roller on both side of the C-BEAM extruded rails for added strength. All of the plates for this were created using the C-BEAM machine I completed several month ago.

-

-

-

- Build Progress:

-

- Build Complete!

Attached Files:

DonLinTX, Donald F Lytle, Jay Lytle and 10 others like this. -

-

Build Author anigeek65, Find all builds by anigeek65

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution - CC BY

-

Attached Files:

-