Hi peeps,

My name is Budiman and I'm from Jakarta, Indonesia. I do graphics and multimedia here and want to start doing product design. Googled around for a good cutting/shaping tool, and found out about cnc router. Upon further googling, I came across shapeoko, openrail and finally openbuilds OX . OX gives me more size flexibility without a pre-packaged bundle and I think openrail and vslots are elegant solutions for linear guides.

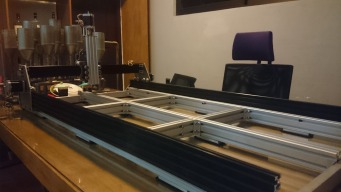

After I decided to go ahead with openbuilds OX, I kept thinking of ways to incorporate regular aluminium profiles to the build to minimize shipping cost. I could have used openrails but having not seen and handled personally the wheels,belts, rails etc., I would rather keep the unknown variables to a minimum. So, v-slots for linear guide/gantry parts and regular aluminium profile for the rest. With this, I could go ahead and build the bed support with locally available parts while waiting for the specialized parts to come. The bed support was finished last month

I have been thinking about using double belt to have that extra accuracy. Did some research and found out that some of you guys are having the same thought too. I think one of the problem would be how to fit them inside the vslot and make sure they do not move around and tensioned enough. I bought some wire reinforced 50mm gt3 belt and cut them to 7mm strips. Am thinking of attaching that belt to the bottom of the slot using double tape. The end of the bottom belt will be held by teenut and screw. The top belt will fold over the buckle. I used cross sections of a lighter as belt buckles and tensioners. I did try to pull the top belt manually to test the lighter plastic strength and it held. I am not so sure how strong the pull will be when the machine moves. I did not pull gently tho. (pardon my cat's and dog's hairs in the photos) Any pointers guys?

I had to add aluminium bars below the 3060 profile to make the slot align with the 2080 slot. Used teenuts and screws to attach both profiles together. Since I ran out of precision shims and spacers, I also used teenuts as the spacer between both profiles (35 mm screw - drilled 3060 - tee nut - tee nut - 2080). Need that space to clear the bottom wheels' nylon hex locknut movement. There are rubbers between the machine/bed and the table to minimize vibration during operation.

Enough rambling for now, please check out the pics. Please keep in mind I am a total noob and I would still need contructive critisms and inputs from you all. Special thanks to Chris Laidlaw for the z axis plates and makita router mount and @asb_79 (Anthony Barber) for the gantry plates and for listening to my rambling and giving me inputs for my build. Thanks Mark (kram242 for the openbuilds parts and shipping) and Michael from sparks concept for the cnc controller (still waiting for it!)

Best regards,

B

OXford (OX fortified)

Build in 'Cartesian Style CNC' published by d0rk1e, Sep 24, 2014.

150x75 cm OX with additional Y axis supports and hopefully a working double belt system

-

-

-

- Build Progress:

-

- Build in Progress...

-

Special Notes

Use 30x60 aluminium profile for bed and y axis support

Hendy, duki, Mark Carew and 1 other person like this. -

-

Build Author d0rk1e, Find all builds by d0rk1e

-

- Loading...

-

Build Details

- Build License:

-

- CC - Attribution NonCommercial - Share Alike - CC BY NC SA

Inspired by

Openbuilds OX