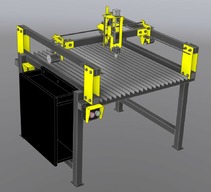

Functional real-world build with RM2-2RS bearings in routed V grooves on phenolic resin rails (lab countertop scraps) and NSK linear rails/trucks for Z and floating Z switch. Plasma cut steel components - several with easy bends. CNC routed Columbia Purebond hardwood plywood and resin components. XL belts on OpenBuilds smooth idlers with 688 bearings. Asian T8 "ACME" lead with "brass" nut (3D printer component). NEMA 17 with captive lead on Z and NEMA 23 for X and Y. Cost was apx. $300 excluding electronics.

Gecko G540, Mesa FPGA and 2x THCAD with LinuxCNC (qtPlasmaC) on HP DeskPro 400 G3 Mini. Inductive sensors for X, Y, Z, A, and floating Z switch. Second THCAD supports Ohmic sensing. 24 and 5V DC power supplies.

Expected wear in v-grooves routed into the phenolic rails hasn't appeared. A slight "glaze" appeared in the grooves and no bearing adjustments have been necessary since initial assembly.

This has since been scaled up to 50x50" with similar results.

Z axis doesn't need an anti-backlash nut due to precision added by THC. There have been no issues with the tiny/low quality NEMA 17/captive lead.

Attached Files:

Plasma Table 006

Build in 'Plasma Cutter Builds' published by xyzzy603, Oct 9, 2022.

Fast, inexpensive, near-zero maintenance, and 2+ years of near-daily use.

-

-

-

- Build Progress:

-

- Build Complete!

Milton Esquibel, Tomas Pontes, C. Tyson Fisk and 1 other person like this. -

-

Build Author xyzzy603, Find all builds by xyzzy603

-

- Loading...

-

Build Details

- Build License:

-

- CC - Creative Commons Public Domain (CCO 1+)

Reason for this Build

Needed small plasma table at home.Inspired by

Low maintence of plasma tables with RM2 bearings. -

Attached Files:

-