M4: 1510SS Heavy Mk.I

Discussion in 'CNC Mills/Routers' started by Rob Taylor, Aug 22, 2020.

M4: 1510SS Heavy Mk.I

Discussion in 'CNC Mills/Routers' started by Rob Taylor, Aug 22, 2020.

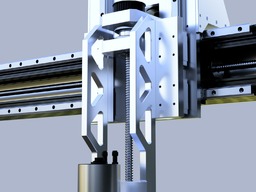

A 1500x1200mm, 20mm rail and 1610 ballscrew, heavy-duty, four-axis gantry machine. As high speed as spindle power MRR will allow for. Approx 4 x 3 x 1ft travels, intermediate size between benchtop and floor-scale units. Aiming at $10-15k machine in the $3k region.

Page 1 of 2

Page 1 of 2