X/Y Table Style CNC Mill

-

X/Y Table Style CNC Mill

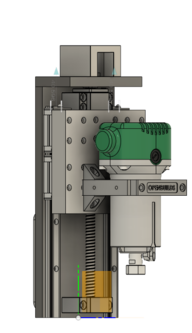

Workbee Z-axis Upgrade

Z-Axis upgrade with linear rails, SFU1204 Ball Screw and full aluminium construction.

Keeping thing quiet with a custom C Beam XL

A small form factor machine in a soundproof enclosure

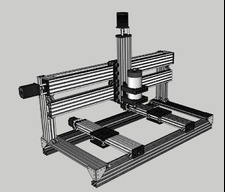

Homemade CNC Router (Under $400)

So Instead of buying a CNC Router which can cost thousands of dollars I ventured on the quest to design and build my own. I have multiple parts to this series. Hopefully all of my information I share helps!

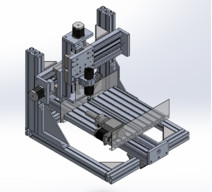

Fixed Gantry Easy Assembly

Fixed Gantry CNC with good accuracy and rigidity but for a higher price than the usual CNC's on the site.

Denford CNC Resurrection

Denford CNC Mill Update

Reworked Sepcraft 420 CK

Its alive !

Build Author

dcarlisle

Views

10696

Build Author

dcarlisle

Views

10696

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

Build Author

Joe Garritano

Views

11566

Build Author

Joe Garritano

Views

11566

X-carve upgrade

Using criticall OpenBuilds components to upgrade the rigidity and reliability of an X-Carve 1000mm build.

C-Beam Elexa

This build will be based on the C-Beam Plate Maker, with additional changes based on other builds and ideas.

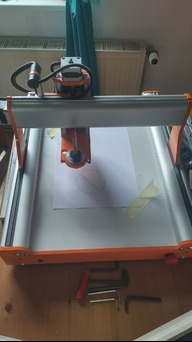

First build - small scale

Using basic standard components, beams, motors, belt drive on x and y, z is a screw. Using Grbl Panel on Windows 10. Really basic router, had trouble getting the controller to turn on the router and set speeds so it is currently wired to a power bar switch so it runs full speed and I just use the switch to turn it on and off. Just getting x, y and z control working properly for now and likely going to switch the router to my dremel 4000 using a 3d printed mounting bracket I got from thingiverse

Noob 1000Sphinx

A complete noob stumbling thru his first cnc build in winter.. and trying to find the time with 2 toddlers..

ApiNui - CNC Router ( an oversized workbee )

Based on the WorkBee CNC, this is an oversized router built with a specific use-case in mind, for manufacutring beehives, and beehive components

Build Author

Jose Alezandre

Views

2173

Build Author

Jose Alezandre

Views

2173

Mighty Chihuahua

The idea was to use materials from previuos failed projects into a succesful one. I have build this tiny but powerfull CNC machine mainly using the universal gantry plates for the X and Y axis. Also another innovative part is the fact that I assembled the Z gantry with 2 aluminum sections of 20X40 and one aluminum seccion of the 20X20. I used NEMA 17 stepper motors with GT2 pulleys. This was designed on Fusion360

First CNC Router

My very first CNC Router build. It's completely scratch built.

My large machine 48 X 48

This machine is controlled by a Mach3 BOB. I USED Nema 34 stepper motors and a 3kw, water cooled spindle. I’m in the process of adding a vacuum table with 4 zones. I have an X-carve so I use Easel to create G-code for the large machine. I’m currently looking for a way to stabilize the Y-axis. It wiggles a little, so I want to add another linear rail high on both sides.