Build List

-

Active Filters:

xpro

Build Author

Spark Concepts

Views

17092

Build Author

Spark Concepts

Views

17092

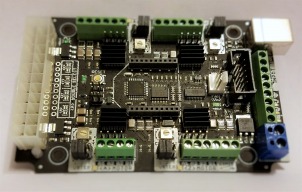

CNC xPRO V4

Take your build to the next level with the CNC xPRO V4!

Build Author

Spark Concepts

Views

75130

Build Author

Spark Concepts

Views

75130

CNC xPRO Driver

Spark Concepts CNC xPRO Driver. A new GRBL compatible, all-in-one stepper driver board with 4 motor controllers for XYZ + 1 clone (or rotary!). Capable of powering your next build with an ATX PSU (or 12V 2 wire supply), and ready for wireless printing. Compatible with Arduino (wireless robots anyone?)

Build Author

joetemus

Views

28111

Build Author

joetemus

Views

28111

K40 ACRO Conversion

A K40 to ACRO Co2 laser cutter build. Designed and built to expand the work area of the K40

Lead 1510

Customised Lead 1010 making it a 1510. T-Track work area with dual Y limit switches for auto-squaring. Powered by xPro v5 & CNC.js

Build Author

RobSaunders

Views

17355

Build Author

RobSaunders

Views

17355

Laser Cutter/Engraver OptLaser 6W with Z-axis

This was my first attempt for a laser platform. I'm using the OpenBuilds ACRO 20"x40 platform, 6W OptLaser, homemade z height and the xPro driver board.

Build Author

msdosfx

Views

6321

Build Author

msdosfx

Views

6321

Workbee 1510 Screw Driven

Workbee 1510 screw driven build by MsDosFX.

Build Author

Spark Concepts

Views

5546

Build Author

Spark Concepts

Views

5546

MPG Jog Controller for CNC xPRO

Been playing around with an MPG Jogwheel

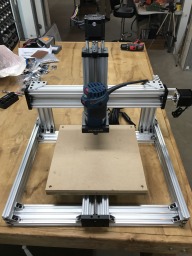

Non OX CNC Router

This CNC Router is to 95% made of standard parts and almost all of them from the http://openbuildspartstore.com/.

Build Author

Rick Holder

Views

15585

Build Author

Rick Holder

Views

15585

Gantry Type CNC with Makita Router

The machine has met and exceeded my expectations on repeatability and accuracy. Cost was approx £600 including the Windows tablet.

Build Author

Carl Siren

Views

7790

Build Author

Carl Siren

Views

7790

CNC-machine 650by700

A home-made CNC-machine with a 1.5 kW air cooled spindle motor suitable for milling materials such as wood, plastic and soft metals. The work table is 650 mm wide by 700 mm deep and the maximum movement is set to 560 mm for the x-axis, 480 mm for the y-axis and 105 mm for the z-axis.

Build Author

pedrofernandez

Views

8064

Build Author

pedrofernandez

Views

8064

ACRO 20x20

The Acro Laser Machine Build

Build Author

ShockingTops

Views

4602

Build Author

ShockingTops

Views

4602

Opening into doors

Construction of a CNC table for a specific project that could cut an area larger than a door (>8'x4'). Much thought went into how to avoid the weight of the gantry bending the (long) Y axis, whilst still keeping down the complexity and cost.

Another (Mostly) Stock OX

For my first Openbuilds project, I decided to put together an OX CNC Router.

Nebraska 1246 x 1184

This is my first attempt at a CNC anything build

Arctic_Stingray CNC

This build is based on the C-Beam build by Mark Carew. I have added axis limit switches and a remote mounted control cabinet. This build also uses a custom moveable table.

C-Beam Big Mouth

My first build was with the basic C-Beam Build. I soon found the z clearance a little constricting So I added 2 500 mm actuators to support the x axis rail . I also left off the front and back y axis support rails for easy cleaning. I mounted the base of the machine to 1/2" mdf with 10/32 screws and blind nuts.

Cebu

Another build based on the venerable OX. xPRO CNC controller, and a few extras.

CNC Router (Non OX)

My own Design (not an OX Derivative) using standard Parts.

Build Author

dcarlisle

Views

10872

Build Author

dcarlisle

Views

10872

pain in my ox

build is in process the machine went together perfectly no issues at all but the software is another issue I have been trying to get the thing dialed in it is driving me nuts I'm still in the process will update if I ever get it figured out

The FOX

This will be an OX based machine which I've designed to make the best use of my materials, be as precise as the design allows and operate as quietly as possible. I live in an apartment complex so space and noise are two important factors for me. Therefore the machine needs to do as much as possible while using little space and not annoy the neighbours.