Build List

-

Active Filters:

lathe

Build Author

Alexander_Bulgaria

Views

1892

Build Author

Alexander_Bulgaria

Views

1892

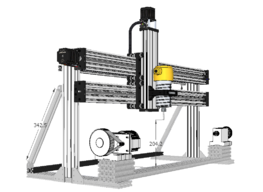

CNC milling machine,lathe,gantry,fdm,clay 3d printer ALL IN ONE

That is the only cnc you will need for most of your diy projects.

LEAD Lathe

I have been toying with the idea of making a 3 axis rotary CNC machine for awhile. I wanted to make it with off the shelf OpenBuilds parts so any one can replicate it and I felt the LEAD High Z Mod would be a good starting point.

Y table for LEAD Lathe - essentially a High Z Cbeam XL

I built the lathe as a dedicated rotary axis, but I soon realized I could have a back up CNC for very little expense.

Build Author

Jason @ MCC

Views

13571

Build Author

Jason @ MCC

Views

13571

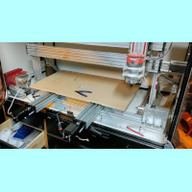

QueenBee Pro CNC Router and Lathe

A 1000x1500mm QueenBee Pro with a 4th Axis Rotary attachment/Lathe Bed.

2 Axis Lathe cutter

Rubber company use as a lathe cutter for accurate cuts compared to hand cutting.

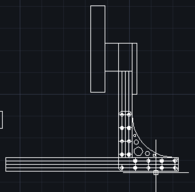

Mini lathe CNC Conversion - Work in progress

My on going build of CNC Mini Lathe

DRO

Belt drive linear scale for Mill and Lathe

Massive Hotwire Foam Cutter

CNC Hot Wire Foam Cutter. Lathe, Turntable and 4 axis Cutter. Can cut XPS and EPS.

OX TWO in ONE

What I'm doing is pretty self explanatory. I've put a few pictures up

Build Author

Joe Young

Views

6099

Build Author

Joe Young

Views

6099

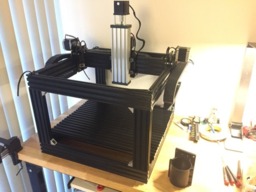

Goliath - CNC + 3D printer Hybrid

Mostly for Mill work, and FDM 3D printing (mostly Nylonx). I'm currently in the process of adding some hardware for a project requiring lathe work. I've included a solidworks 2014 pack and go for those of you interested in the build. if you need another file type, just let me know and i can try to accommodate. This is a scratch build (electronics and hardware)... see photos. Everything is pretty close to industrial quality... Electronics too. I got sick of other COTS designs breaking down

Desktop 4-Axis Nema 23

This build is specific to a furniture design I am trying to bring to market. My first attempt to build a machine. I have looked at other build submissions to help me figure out where I would like to start. The workable volume should 36" W x 6" D x 6" T. The goal is to become more comfortable with the electronics side of machines I enjoy using and also lower the cost of my product by reducing man hours in the manufacturing process. Yay!

CNC Lathe Upgrade

So, not much here, as I'm still building, but I'm putting in the work.

Build Author

Weldsmith

Views

7901

Build Author

Weldsmith

Views

7901

CUT SMITH

I am building a multi tool CNC. I plan to have a quick change tooling system that will accept Routers, oxy acetylene torch, Plasma torch. etc. there will be a water bed under the convertible router table / work bench. The inspiration to build this machine is from having a small garage and not a shop.

Build Author

Blyn3D

Views

6602

Build Author

Blyn3D

Views

6602

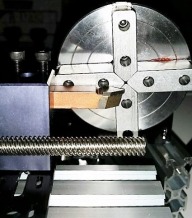

Fourth Axis Mill Prototype

I really like the 4th axis I purchased a few years back, but when I went looking for it again the suppliers who once carried it no longer do. Anyone know who makes it? Center hole receives collets. I own a ShopSmith so I am using a 5/8th rod and can mount it's chucks onto this machine. Also I like the use of the skateboard wheels, they are adjustable and one could use more sets over a longer axis. The Sherline z-axis is not my first choice, I just had a spare.

Build Author

Rakmup

Views

41667

Build Author

Rakmup

Views

41667

CNC Router Lathe

Steel square tube frame with dual feed gantry and indexing lathe section. Will have 36" x 30" x 6" travel. Has a Harmonic Drive on the 4th Axis.

OBlathe

A simple wood turning lathe.

Lathe 4" x 40"

This is a lathe. I do not plan on making parts for NASA, but I want to be able to turn, face and bore things like wood, brass, aluminum and plastics.