Build List

-

Active Filters:

vacuum

Build Author

Gary Caruso

Views

25224

Build Author

Gary Caruso

Views

25224

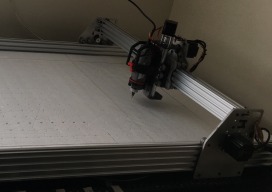

OX Heavy Duty Build

OX Heavy Duty, using Chrisclub plates, for 2080 X-Y and C-beam Z

Build Author

rengelking

Views

41441

Build Author

rengelking

Views

41441

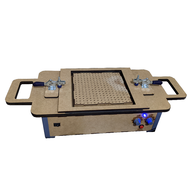

Vacuum Forming Machine

Vacuum Former built with off-the-shelf parts, works perfectly every time!

DIY Vacuum Hold Down table

A simple vacuum hold down/clamp set up using a 6hp canister vacuum.

Suitcase Vacuumformer

Quick overview of my build up for a vacuum former that is self contained, portable and fairly easy to build.

C-Beam Sphinx Vacuum

A modified 1000x1000 Sphinx, with a built in vaccum table.

Build Author

OpenBuilds

Views

12244

Build Author

OpenBuilds

Views

12244

Swing Arm

Simple Swing Arm Build for the Modular Table Series. Create a simple vacuum swing arm that swings over your machine keeping your vacuum hose and router cord, etc. up and out of the way

Build Author

Krishnakumar

Views

9025

Build Author

Krishnakumar

Views

9025

Hobby OX CNC

This "hobby OX" CNC is built for multiple purposes such as cutting and engraving various materials, laser etching and cutting, etc... Its a great platform for hobby enthusiasts like me where this machine can be used for so many different purposes effectively and efficiently!

OX Fixed Dust Shoe

A simple fixed dust shoe for your OX.

Build Author

lekey

Views

12825

Build Author

lekey

Views

12825

Modular Desktop Vacuum Former

This is a small desktop vacuum former that can be connected to a shop-vac and an electric heat source (like a grill for instance). You can control the time each appliance stays turned on, and the vacuum is automatically turned on when the tray is placed on top of the model. The vacuum table is 20x20cm wide, and I've tested it mostly with 1mm thick PET sheets.

Build Author

Craig Hollabaugh

Views

5160

Build Author

Craig Hollabaugh

Views

5160

Hyatt and My Journey to Tonehenge

I'm conducing guitar loudspeaker cabinet fabrication technique research (material type/thickness, mechanical joints, adhesives, etc) and how these relate to cabinet/speaker coupling and enclosure resonance with respect to psycho-acoustics. Basically, does one speaker cab sound better than another and why?

Build Author

Stan Howe

Views

3501

Build Author

Stan Howe

Views

3501

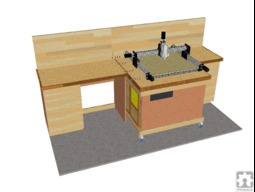

Bee the Boss

The frame of the CNC is going to to Bee a basic Work Bee with maybe 1 modification to the spoil board attachment. This will be located on a custom bench housing the electronics and vacuum. I plan to install Stepper online steppers, drivers, power supplies, and break out board. I will add a 1.5 KW water cooled spindle, with a radiator. The fans from the radiator will pull air from a filtered enclosure for all the electronics.