Build List

-

Active Filters:

tool

Tool position setting Part I

The method used for tool position setting is a matter of personal choice but this is what I do.

Tool position setting Part II.

The method used for tool position setting is a matter of personal choice but this is what I do.

Tool position setting Part III.

In this, the final part, I would like to introduce Machine Vision and show how it can be used, not only for tool position setting but also for resolving the triangle to calculate the G68 (local system rotated) for jobs which are not squarely placed on the work table.

Build Author

j0achim

Views

12525

Build Author

j0achim

Views

12525

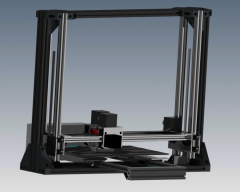

CoreXY - e3d inspired

CoreXY printer heavily inspired by e3d's new open source printer with tool changing. I intend to make it so when e3d start selling toolheads these can be added to the machine without any major work having to be done.

Build Author

mirage335

Views

7485

Build Author

mirage335

Views

7485

TazStiff

Portable, high-speed, low-cost advanced multi-tool desktop factory derived from LulzBot Taz and TazMega.

Build Author

Ariel Yahni

Views

6840

Build Author

Ariel Yahni

Views

6840

OB 2x72 Belt Grinder

Build a 2x72 Belt Grinder out of OpenBuilds V-Slots

CNC accessory box Made 100 % from recovery materials

Quick construction. A few pieces of wood recovered in the trash can, two hooks one hinge, a few screws and a little glue. [Edit] Added the SVG file for sharing (I forgot it)

CreoBot

T-slot, v-slot, aluminum angle make up the majority of the structure.

Build Author

AK-Creation

Views

15141

Build Author

AK-Creation

Views

15141

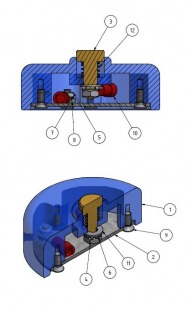

Reference sensor for CNC Tools

For the x and y Axis you set the zero point with a limit switch, but how can you get the zero position for the z Axis? You have different thickness of material to mill and when you change the tool, you have also a other z Axis positon. With the Sensor, you can define the zero position of the piece automaticly.

Kruk 0.1

This is a stool, designed in 18mm wood for a cnc router, it's easily scaleable to different wood-thicknesses, in 18mm wood it takes up 1200*1200mm. It can be assembled without screws, nails or glue and can therefore also be easily disassembled.

C-beam upgrades to my power tools

Just some repairs and upgrades to my drill press and mitre saw using c-beam.

Build Author

Mark Rehorst

Views

10362

Build Author

Mark Rehorst

Views

10362

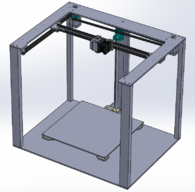

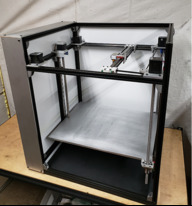

Ultra MegaMax Dominator CoreXY Printer

My self-designed and built, tall-format coreXY printer with 300 x 300 x695 mm print capacity.

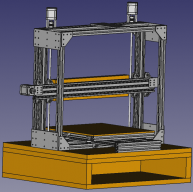

Core XY Beast

Super solid core xy build inspired by the e3d tool changer

Build Author

shanehooper

Views

16344

Build Author

shanehooper

Views

16344

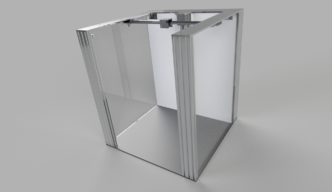

SolidCore CoreXY 3D Printer

Modular and Scalable CoreXY Printer with all metal parts.

Build Author

robert christensen

Views

1783

Build Author

robert christensen

Views

1783

Tool holder

I saw a video of some one pouring resin in a mold,so i did a little research, i bought some resin,and some molds and magnets all from Amazon, it took me several tries and a big mess but it finally finished. The first pour i poured a small batch to make a templet,i marked all the holes that needed drilling then i marked the underside of the mold where i wanted the magnets, next was making the pcs i needed