Build List

-

Active Filters:

mach3

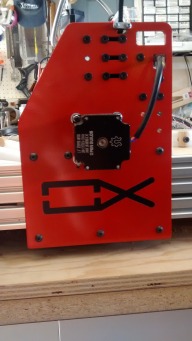

Hot Wire 4 Axis CNC Foam cutter

This build uses drawer slides and thread rod to create foam wings and fuselages by passing a hot wire through the foam which makes very accurate shapes. I built a Radio Controlled SuperVC10 using foam but did have a cnc machine then so I had to make many templates to guide the hot wire. This inspired me to build a cnc hot wire cutter. Works really well and have made several RC models with it now

Build Author

Steve hope

Views

19335

Build Author

Steve hope

Views

19335

8x4 CNC build

Routy cnc upgrade.

1500x1000 (4x2) Router - OX derivative

OX build with 1.5m gantry the 1m deep table.

Tall OX

After completing a standard OX build, I found I didn't have enough Z-clearance and designed a set of taller gantry plates

Build Author

JWhitten

Views

14295

Build Author

JWhitten

Views

14295

Build #2 - Bigger & Stronger

Large format CNC router with a 1500mm x 3000mm cutting envelope (5 x 10 ft) strong enough to cut wood and aluminum constructed from 20-series and 40-series aluminum extrusions. Complete Project Log w/ Pictures: https://goo.gl/photos/Co81AvGwVijE2zow9

Build Author

Rob Mahan

Views

14129

Build Author

Rob Mahan

Views

14129

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

C-Beam "2" XLarge CNC Router

C-Beam 2XL CNC Router

Beaver's OX 1500

OX 1500mm x 1500mm w/1.5Kw Water Cooled Spindle & VFD ran by a Gecko G540 & Mach3

Build Author

Tucstrlly

Views

9198

Build Author

Tucstrlly

Views

9198

Stainless OX Kit Build "Diamondback CNC"

A copy of the Stainless Ox by Martin Barfoed. Similar design, construction and control.

My large machine 48 X 48

This machine is controlled by a Mach3 BOB. I USED Nema 34 stepper motors and a 3kw, water cooled spindle. I’m in the process of adding a vacuum table with 4 zones. I have an X-carve so I use Easel to create G-code for the large machine. I’m currently looking for a way to stabilize the Y-axis. It wiggles a little, so I want to add another linear rail high on both sides.

My Little OX

This build has been an educational experience. Software and hardware alike.

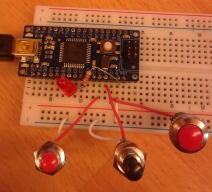

USB Pendant

An USB Pendant for LinuxCNC / Mach3

Build Author

Gary Bonard

Views

6294

Build Author

Gary Bonard

Views

6294

OxZilla

This is my second Ox with a working area of 14" x 14" x 5" I wanted to build a small sturdy potable CNC router and this OxZilla has the nice upgrades !

Build Author

Tomas F Uribe

Views

5428

Build Author

Tomas F Uribe

Views

5428

Atucnc

2 1/2 axis CNC chassis. Convertible to plasma, 3D printer and welder. Currently used as router. Plotting table dim: X axis 620 mm, Y 650 mm, Z 100 mm. Created for teaching purposes, open source license, currently used for engraving ukiyo-e wood plates and printmaking

Bedroom Builds (BrB) DIY CNC

So I am employed in the automotive industry and I walk by thousands of dollars of CNC products daily that are no use to me due to being a Technologist and not a machinist. So therefore with some research I found openbuilds and their great selection of products to build my own CNC. This CNC will consist of 4 axis one removable 360 degree axis for turning alongside a x axis table Y axis stationary gantry and a Z axis attracted to the Y axis linear actuator.