Build List

-

Active Filters:

ramps

Build Author

Sheepdog

Views

26775

Build Author

Sheepdog

Views

26775

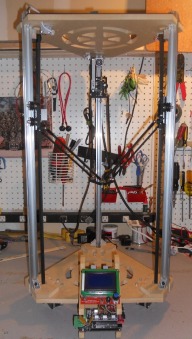

Griffin Delta Printer

Designed from the ground up as a low cost, highly scalable delta printer. This printer has been built as small as carry on luggage size, up to an 18in wide print surface and is capable of larger. Approximate cost is low to mid $500 range start to finish, including electronics for a basic model.

Build Author

nicklogan

Views

16957

Build Author

nicklogan

Views

16957

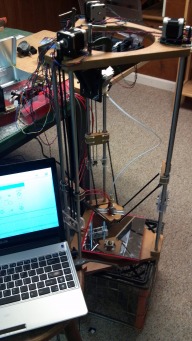

MDF Delta

A Rostock style delta bot with the parts which are typically 3D printed made from medium density fiberboard (MDF). It uses a home made hot end.

V-slot and MDF DeltaBot

This is a deltabot 3D printer build using CNC routed MDF and v-slot rails. Full description found in instructables.com.

MOJO 3D

Fast, Large build area, CoreXY design

Build Author

Naomi Wu

Views

10761

Build Author

Naomi Wu

Views

10761

Naomi Wu's Automatic Bartender- BarBot!

This is an automatic bartender- a BarBot, designed to be made with off-the-shelf OpenBuilds, V-slot and low-cost 3D printer parts.

Build Author

Keteland

Views

10688

Build Author

Keteland

Views

10688

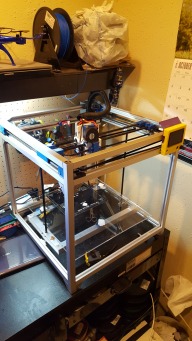

MULIMATERIAL 3D PRINTER (in progress)

ELECTRONICS - ARDUINO Mega 2560 + RAMPS 1.4 + power supply 12V - Leadshine DM 5042 external driver + Power supply 36V + NEMA 23 stepper motor SOFTWARE - Repetier Host to communicate with the Ramps - ARDUINO to upload the firmware (Marlin) MECANIC - V-Slots rails 40x40 + home-made plates - everything goes fine on the side of the build

Build Author

recoush

Views

9211

Build Author

recoush

Views

9211

CoreXY 3D build one

an 8020 build with 1010 extrusion (1") Square tubing Rough size is 24x24x36 (600x600x900) The expected usable print area 21.5x21.5X32"roughly (510x510x760) An XY 3D printer with 3 extruders and 3 Z-axis 0.9 degree motors the table (Z-AXIS) will lift up to the XY Carriage on 3 12mm linear rod and 3 8mm Lead screw's Corexy designs complete and Z-axis build is started don’t have a 3D cad system yet so building my prototypes on a pcb layout tool

Build Author

Sam Dobbie

Views

7778

Build Author

Sam Dobbie

Views

7778

the STD

A fully aluminium printer made from off the shelf components, no printed parts.

Build Author

Fabio Orsi

Views

6919

Build Author

Fabio Orsi

Views

6919

147 RepStrap 002

This project is focused on developing a low-cost, portable and open-source FDM 3D Printer.

Build Author

JerwanDavis

Views

6054

Build Author

JerwanDavis

Views

6054

Coined by my family as the: Davomatic

Build Notes: Here are all the parts necessary to re-produce this design. Please note, all of the parts are either sourced through openbuilds or have been selected and printed from thingiverse.

Vertical Drill Mill

Mill drill using a dremel and some 3d printed parts

Atlas Delta Bot

The idea here is to build a nice large delta bot from the parts ground on the one builds part store. Other parts that are sources out side of this will be detailed. I have a simple BOM I started that I will upload later.

Build Author

MidnightQuads

Views

3879

Build Author

MidnightQuads

Views

3879

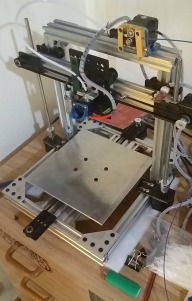

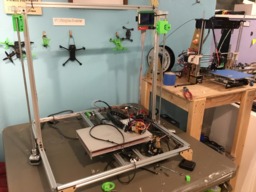

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

Build Author

bpatterson42

Views

3540

Build Author

bpatterson42

Views

3540

Inverted Y C-Beam Machine

Similar to C-Beam Machine build, but with inverted Y-axis assembly to shield drive screw. Integrated XZ gantry can be fixed to any solid surface. Build dimensions are 36" x 36" x 6".

Build Author

David E. Flores E.

Views

3266

Build Author

David E. Flores E.

Views

3266

F-Ender-Plus 3D Printer

F-Ender-Plus its based on the Ender 3 Pro, but improved: CR-10 hotend, double gear extruder, double z-axis motor, bltouch incorporated, hotbed leveling improved strings kit. Most made using local vendor parts, and still I'm increasing my knowledge of how get better 3D printings by calibrating motors steps, leveling the hotbed and z-axis; using a 3mm thick glass...

Build Author

Terone Burgenheim

Views

2812

Build Author

Terone Burgenheim

Views

2812

My CNC

This build is my version of the CBeam machine. I opted to NOT use the Gussets, and instead went for the 40, and 60 mil angle brackets to cut the price back a little further. I started with the smoothieboard but decided it was still "too new" and very much experimental. This build took me a few (2-3) days to complete. The CBeams and Lead-Screws really make building things faster since you don't have to clamor over belts.