Build List

-

Active Filters:

large

Build Author

naltek

Views

1472

Build Author

naltek

Views

1472

NALCNC: New Open-Source High-Performance Modular CNC System | Large Format Kits & Machines

NALCNC: New Open-Source High-Performance Modular CNC System (MPCNC Evolution) – Large Format Kits & Machines

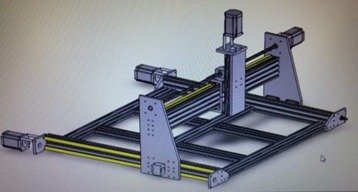

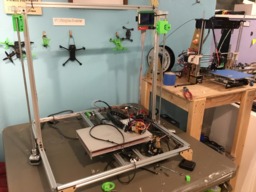

XYZ Factory Bot

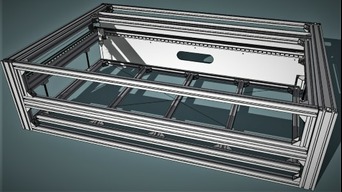

Very large format build platform designed really for printing multiple items in one session ether all the same or different. Longer term I would like to have multiple X axis on the Y axis rail. bit of a slicer challenge though.

KRE CO2 2x4 Laser

Large Format CO2 Laser Cutter

Build Author

tshilling

Views

39313

Build Author

tshilling

Views

39313

K40 12x24in rebuild (In Original Case)

Rebuilt the internals of a K40 to allow for a 12 x 24 in cutting area while reusing the same external case and not touching the laser tube.

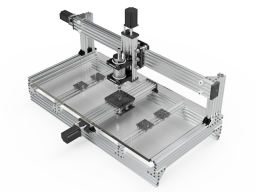

C-Beam Machine XLarge

A rigid and wide format, plate and carving CNC.

THE BIG GREEN MACHINE

1500*1500*1900 (xyz) Biocomposite Pellet 3D printer

Build Author

nc3dpw

Views

24835

Build Author

nc3dpw

Views

24835

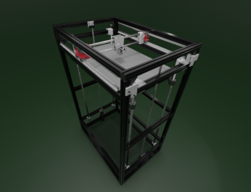

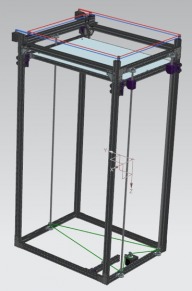

(Portable) Large Format 3d Printer 4ft square frame. Build Volume 36in x 36in x 36in

Large format printer build based off successful small Corexy. I figured it could be scaled to large format and be portable. Portable meaning by removing a few pieces it could effectively be rotated out of a standard door frame.

Build Author

James Archer

Views

14740

Build Author

James Archer

Views

14740

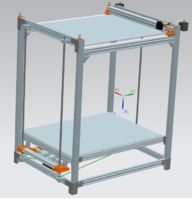

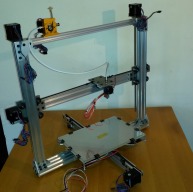

Archer - An extendable all metal 3D printer

This is an all metal build using OpenBuilds V-Slot linear rails to produce a high quality and cost effective 3D printer. The printer is designed to be scalable for your desired build area and can utilize high quality hotends with 16mm groove mounts such as E3D.

Build Author

Serge E.

Views

61441

Build Author

Serge E.

Views

61441

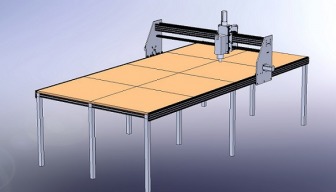

myOX : a 4' x 2' OX CNC with potential

This is the story of me building myOX - my version of the "ideal" OX. I want a machine which can route/mill at least 4' wide and as long as I can feed through (don't be shy, think "infinity") as well as going deep on multiple faces - manual 4th axis. I have loads of ideas to take myOX towards that goal and way beyond. Time will tell. Just follow along through this build and possibly a few others along the way ... Check out my OXCalculator : let your computer figure out your BoM

Stabilus 3d Large Format Printer Kit

Stabilus 3d Large Format Printer Kit

Build Author

crypt-tek

Views

34701

Build Author

crypt-tek

Views

34701

C3DO

My first 3D printer build. It is almost complete and will be posting the first completed print shortly. I still need to mount the print spools and a couple other odd ends to complete this.

Build Author

Mike Campbell

Views

11431

Build Author

Mike Campbell

Views

11431

bor 454-D

A large format, modular, rack and pinion build designed around OpenBuilds components.

Build Author

shanehooper

Views

28700

Build Author

shanehooper

Views

28700

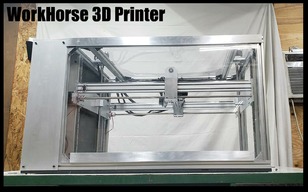

Workhorse 3D Printer

Large 600mm x 350mm x 350mm Build Volume with lead screw driven motion. The printer build has a moving gantry and fixed heat bed. Open Source

3000x1500 CNC

Here is my Project A CNC 3000 mm by 1500 mm, with a 2.2kW spindle collet ER25 and 4 stepper motor nema 23 425oz-in. The purpose being to have a large work surface for a minimum cost.

Build Author

sebf34

Views

32442

Build Author

sebf34

Views

32442

OX Based cnc 3000 x 1500 Double belt

OX Based CNC

Voxel Evolution

This is a remix of Marshal Peck's Voxel OX, with some design tweaks inspired by Makerparts and jjcolletta. It has a build area of 300mm X 300mm X 480mm, but is easily configured for just about any build area up to 500mm X 500mm X 750mm. I have used some laser cut acrylic plates and a couple of 3D printed parts in its construction, however it can be assembled using nothing but OpenBuilds parts with the exception of the heated bed and the Y axis carrier for the heated bed.

Build Author

Robert Mech

Views

10349

Build Author

Robert Mech

Views

10349

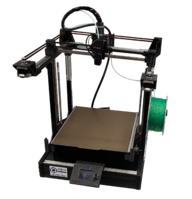

LayerFused X301 - CoreXY Large Volume Printer

The X301 is a CoreXY 3D Printer that has a small footprint and a large 300x300x330 build area. The open style of this printer breaks the "Cube" mold of many other printers in this class but still retails rigidity and great performance.

KeePrint Monster

Large 2 foot x 3 foot x 4.5 foot build volume Core XY printer build in process at this point. I am designing everything from scratch and using typincal parts bought from amazon for the build.

Mushu - Large Scale CoreXY

20x26x28 inch Build Volume CoreXY. Unlike many builds, I've decoupled the XY movements from the Z-Axis lead screws to help prevent Wobble, will be using linear guide rails, and mains powered bed heater, and a bed that is Allowed to thermally grow. This build is JUST narrow enough to fit through a standard sized doorway.

Build Author

RobFromLDMS

Views

5486

Build Author

RobFromLDMS

Views

5486

Lithgow Mens Shed CNC build

The tale of how we put together our CNC Router, and some of the difficulties encountered. It is now ready for final testing and commissioning.

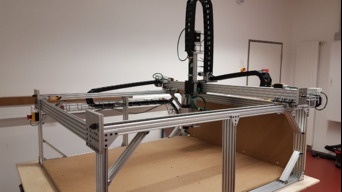

Open source large format CNC-machine and 3D printer

For a schoolproject we decided to build this large format CNC-machine. The greatest part of the mechanics were sourced from OpenBuilds.

Large format plasma ox

I will update this as I go, cad files upon request. My x beam is basically a belt driven r7

Build Author

Rob Mahan

Views

14295

Build Author

Rob Mahan

Views

14295

Rob's C-Beam Machine XLarge

This is my first CNC router build, so I started with the OpenBuilds C-Beam Machine XLarge mechanical bundle, including four high torque stepper motors. I took my time with the mechanical build, sought and found some great help for my control system, and designed and built a custom cabinet to house everything.

Delta without vertices

As this is a build in progress, I will update it as I progress.

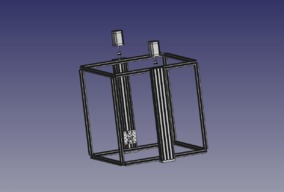

Design and Performance Evaluation of A Large FDM 3D Printer

This build includes the design of a large FDM 3D printer. This machine has a 796mm by 796mm by 900mm (LxWxH) build volume. Motion is controlled by servo motors and the printer runs on python-based marlin firmware.

Build Author

Kyo

Views

6681

Build Author

Kyo

Views

6681

C-beam Delta Printer

Large scale delta robot using c-beam as the core frame component.

NotAnOx

From plywood and linear rail to c-beam. I probably should have bought a kit.

Build Author

Nicademus

Views

9954

Build Author

Nicademus

Views

9954

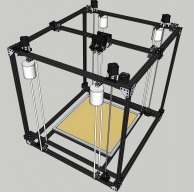

CNC/3DPrint/Laser/Mill (formerly CNC-inator3000)

Ultimately - the design is based on the highly successful Ultimaker concept, for which a regular size costs in the thousands, and one of this size would be edging into the 10's of thousands. Expected Build cost - <$800 It is a X/Y Cartesian printer with Raising/Lowering Z axis (Hotbed.) - Overall size is 610mm x 610mm x 750mm - with build volume of around 450mmx450mmx450mm - and will also have the ability to change work tools - such as for CNC Routing, Lazer etching, 3d Scanning, etc.

Build Author

Glenn Weston

Views

18813

Build Author

Glenn Weston

Views

18813

"The Moagie Mill" My C-Beam XLarge

My Experiences building the C-Beam X Large. Maybe you can pick up a few pointers from my ramblings and experiences if you are considering building this machine.

Inspired by the Crawlbot

Building a couple of CNC's based on the Crawlbot

Build Author

crnrstndes

Views

4378

Build Author

crnrstndes

Views

4378

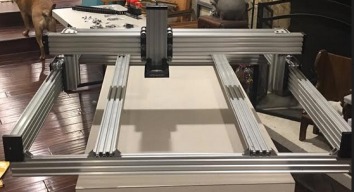

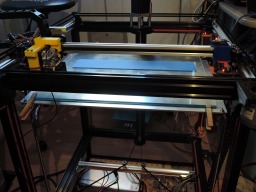

C-Beam Upgrade to Larger C-Beam

My goal was to be able to enlarge my C-Beam with as many original parts as possible. I was able to recycle almost all of them with a only the two 500 mm rails left over. I used 1000 mm rails for the X Axis and I added another complete Y Axis assembly. I chose to keep it simple and I am very happy with the result!

Dogmeat's Custom C-Beam XL

I love the C-Beam XL concept, this build is my custom version with the goal of increasing rigidity for metal milling.

c-beam XLarge with ZLarge

XLarge with ZLarge

Build Author

George Motichka

Views

3896

Build Author

George Motichka

Views

3896

Transformer

I wanted a machine that could easily switch between 3D Printing and Laser Engraving

Build Author

MidnightQuads

Views

4023

Build Author

MidnightQuads

Views

4023

MQTitan printer

Components- RAMPS, running marlin, Nema 17, All metal extruder, 600mm lead screws, 600mm 2020 aluminum extrusions, 12v 30a power supply, 12v LED strip, Typical endstops, 600mm 8mm linear rods, Bearing block for 8mm bearings, Openbuilds plates, wheels, and bearings, 500x500mm borosilicate glass plate

1000mm X 1000mm with tinyg

1000mm X 1000mm overhead cnc machine

Pink Panther - MendelMax variant

Taller and wider MendelMax 1.5 spinoff

Printer number 2

A Large Printer that will hopefully be able to print at least 45cm cubed

Linear Rail derivative with ball screw

basic start to design of cnc machine

InDoreXY

A Large CoreXY build that can just barely get in through a doorway, aiming for under $1000. Build Volume approximately 18in x 24in x 26in.

Build Author

JerryD

Views

5461

Build Author

JerryD

Views

5461

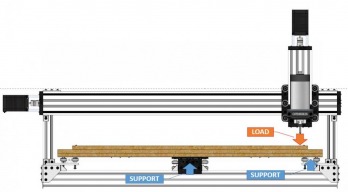

1500x1000mm Adjustable Height

I have the demand to cut/etch tall pieces of material. For this reason, I have designed a machine with 500mm uprights with adjustable gantry height. This way I can raise/lower the sled and z-axis as needed. I've also chosen to use a linear C-channel assembly for the Z axis with the plate mounted to the gantry instead of the other way around. This will allow for maximum range of the z-axis. The parts list/BOM does not include motors/belts/pulleys or electronics.

CORE XY 3D Printer

This is an inexpensive build, large volume 2225 cubic inch, CORE XY 3D printer providing decent speed with precise and repeatable precision with expandable features.

CoreXY Cube

CoreXY cube with 600x600x800 volume.

Build Author

J-Wahl Dezign

Views

9274

Build Author

J-Wahl Dezign

Views

9274

1.4 meter tall build height, 300x410mm build plate cartesian

The original plan was to build a 3d printer with a 1200x1200 build platform with a 600mm build height. I was having issues getting ahold of a large enough borosilicate glass plate for the build so I decided to go for build height. I plan on using a smoothieboard for the controller. The build has currently slowed down. I was removing a broken drillbit from the linear rail mount, and it shattered and took out my eye. I am doing what I can when I can focus my eyes long enough for the build.

Build Author

Thair.nl

Views

3966

Build Author

Thair.nl

Views

3966

Plate Maker Plus

C-Beam Plate Maker with a larger size of the work area and electronics added.

Build Author

eddyg

Views

5139

Build Author

eddyg

Views

5139

OX with a Custom Electronics Case

Embarking on my first build and trying to start with a clean setup by creating an enclosure box for my controllers and power supply.

STEAM Machine

Simple design with a large build volume - 450x450x450

The Artist Formerly Known as Prints

Work in progress large volume CoreXY printer

Build Author

Dmknerr

Views

5329

Build Author

Dmknerr

Views

5329

Server Rack Printer

My first project build. Concept build to use an existing 7.5 ft tall server rack as the frame. This ptoject may never be completed.

3D Printed Solid - Large Format Printer

I need a large build plate without spending 10-20k for a "store" built printer.

Build Author

TouchPadKing

Views

5203

Build Author

TouchPadKing

Views

5203

1500mmx500mm Kossel Delta

Please, look over my build and make any recommendations you can think of! I haven't figured out how long my arms need to be yet. Nor have I done any shopping around to find better prices...

Build Author

Dave420

Views

14725

Build Author

Dave420

Views

14725

10 x 5 ft plazma table build

Attaching V Slot or mutable V Slot end on end to a larger steel frame table.

Moag's CNC Mill

A design in progress, to 3D carve two-part Aluminium injection moulds for Soft Plastic Lures and Lead Jigs, so I can prototype some of the concepts rattling around in my head. All Openbuilds parts where possible, 1000x500mm footprint, 0.8kw Water-cooled Spindle?, High Torque Stepper?,Smoothieboard?, I still have no idea. As a newbie to the CNC world, any wisdom would be welcome to take this from just a idea into reality so I can start playing with all this awesome stuff. Thanks in advance

The Buffalo

OX 1500 x 1000 mm

Build Author

Matt Nelson

Views

12504

Build Author

Matt Nelson

Views

12504

Matt's Ox

I'm building an OX CNC router. It will be the larger size of 750x 1000mm. This should give me a working area of about 22"x30".

bertha

This build will hopefully be 18x18x24 build space using RAMPS 1.4 with Marlin firmware. Using NEMA 17 motors and belts to drive the X and Y axis, lead screws for the Z axis. The build plate will be heated with a delrin Y carriage for the glass and heatbed. Z axis motors will be top mounted. Possibly and ATX power supply.

Ooznest OX CNC for Architecture Modell

While i achieved the desired taler Z axis this was very notable of the cost of the stiffness of the Y axis - the Y axis is now quite wobbly. i do not recommend such a big Z axis on a OX CNC machine where the requirement is a good precision.

Large 3D printer

Hello ! This is my very first OpenBuilds build. It's based on the Maximus 3D Printer, published by mytechno3d : good source of inspiration !

Large Laser cut table build

Large 6 x 10 foot laser table build. New to building CNC

Build Author

Kyo

Views

10778

Build Author

Kyo

Views

10778

Fina

This is Fina; My Lautr3k inspired build.

Large Manual 3d Printer

This is the largest printer I have found. It is also the cheapest. The reason is that it is run by hand, without computer or motors or electronics. Put an object on one side and move the 3d pen while tracing the object. Move the z dimension by turning the crank on the lab jack to move the printed copy down a notch. Be creative!

Build Author

Donald D. Parker

Views

5762

Build Author

Donald D. Parker

Views

5762

BABE - CanUSA Blue OX, bigger than the average OX

This is a basic description of my OX-like build of Babe, Paul Bunyan's Blue Ox. It is a work in progress. The idea has been germinating for about 4 years, with several twists and turns and false starts along the way.

Little Big OX

A complete CNC newbie is tackling a mighty challenge, Not only is he making a CNC router, He's going to try and upsize it.

Build Author

DiggerJ

Views

8939

Build Author

DiggerJ

Views

8939

Babe - The Big Blue (Laser) OX Build

A 1000 x 1500 OX build with the ability to router cut dovetails as well as laser engraving and light cutting.

Leveling Gantry

Large leveling platform to hold a 3hp router